Morgan Advanced Materials Offers New High Frequency, Fine Pitch Piezoelectric Composite Components For Use In High Performance Medical, Military And Sonar Applications

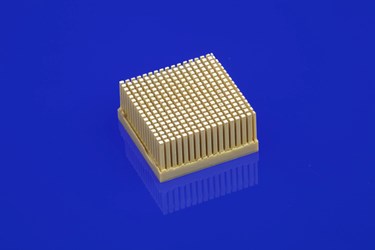

Morgan Advanced Materials, a leading manufacturer of electro ceramic products, including piezoelectric ceramics, high voltage and RF capacitors and microwave ceramics, announces the launch of a new range of piezoelectric composite components, ideal for applications where high performance is critical, including medical imaging, Doppler flow, and military and commercial sonar. Components manufactured with Piezo composite materials offer improved acoustic performance over traditional transducer materials, feature higher transmit and receive efficiency, and can be produced in custom sizes, shapes, and materials.

Morgan’s piezoelectric composite materials drastically reduce the cross-coupling that typically occurs between different modes in the ceramic of conventional transducers, enabling medical components to respond in a more precise and predictable manner. Components manufactured by Morgan also reduce spurious activity,resulting in higher transmit and receive efficiency. These Piezo composite components also provide lower acoustic impedance and improved transducer bandwidth than conventional piezoelectric ceramics.

Morgan offers piezoelectric composites in both 1-3 and 2-2 orientations, in sizes up to 3-inch square and frequencies from 100 kHz to 12 MHz. To enhance transmit and receive response rates, piezoelectric volume fractions can be tailored for any application.

The Piezo composites can be thermoformed to conform to curved, complex geometric surfaces in shapes often not achievable with conventional piezoceramic materials, significantly increasing design flexibility. Morgan’s extensive materials portfolio allows further flexibility as components can be manufactured from standard or custom materials, including Navy types I, II, and VI.

About Morgan Advanced Materials' Technical Ceramics business

The Technical Ceramics business of Morgan Advanced Materials designs and manufactures advanced ceramic components and assemblies.

We work closely with our customers to address their requirements right through from concept to production in quantities from one-offs to high volume. We offer a wide range of advanced ceramic and glass materials, in-depth materials expertise and vast applications experience in diverse markets. We routinely engineer complex parts that enhance the reliability or the performance of our customers’ products in technically challenging applications.

The Technical Ceramics business encompasses the trading brands Certech ceramic cores and Haldenwanger components for thermal processing.

About Morgan Advanced Materials

Morgan Advanced Materials is a global materials engineering company which designs and manufactures a wide range of high specification products with extraordinary properties, across multiple sectors and geographies.

From an extensive range of advanced materials we produce components, assemblies and systems that deliver significantly enhanced performance for our customers’ products and processes. Our engineered solutions are produced to very high tolerances and many are designed for use in extreme environments.

The Company thrives on breakthrough innovation. Our materials scientists and applications engineers work in close collaboration with customers to create outstanding, highly differentiated products that perform more efficiently, more reliably and for longer.

Morgan Thermal Ceramics is a business of Morgan Advanced Materials, which has more than 10,000 employees across 50 countries serving specialist markets in the energy, transport, healthcare, electronics, security and defense, petrochemical and industrial sectors. Morgan Advanced Materials (MGAM) is listed on the London Stock Exchange in the engineering sector. For more information, visit www.morganadvancedmaterials.com.

Source: Morgan Advanced Materials