How To Choose The Right Marking Technology For Your Application

Compare durability, speed, mark quality, and system cost to find the best solution

By Dr. Geoff Shannon, Miyachi Unitek Corporation

Choosing the right part marking technology is becoming more and more important in manufacturing, in response to a growing desire among original equipment manufacturers to trace products over their complete lifecycle. The general thinking among manufacturers is that cradle-to-grave traceability will improve product quality, ensure that suppliers meet quality standards, prevent part counterfeiting, and minimize part recalls.

Each of the major marking technologies — which include laser marking, dot peen, electrochemical etching, and inkjet — comes with its own set of advantages and disadvantages. Manufacturers should select the best technique for a particular part based on such factors as material type, part function, part geometry, surface finish/roughness, mark quality, mark dimension/part size, mark serialization, and coating thickness.

In general, laser marking offers many benefits for direct part marking, because it is faster and more permanent, has a low cost of ownership, uses no consumables, and does not require any further processes to ensure mark durability. Inkjet printing is used as a mark-on-the-fly technology where the part must be moving; typically, mark quality and mark flexibility are poor and the mark is non-permanent. Chemical etching can be excellent for hardened and thin metals. Highly permanent marks made by dot peening can withstand post-plating processes, but mark times are slow and the part must be fixtured, due to the contact of the stylus.

Direct Part Marking Becomes The Norm

Many manufacturers have already moved to direct part marking (DPM), which permanently marks the parts with a serial code, having found that the traditional non-direct part marking techniques (like stickers) do not allow for full life cycle tracing. DPM is used widely by medical manufacturers to facilitate reliable part identification. The part information may be in the form of human readable alphanumerics and barcode or Data-Matrix codes.

Aside from the commercial advantages of part tracking and traceability, another key driver of the movement towards DPM is the mandated requirement for unique identification, as exemplified by the FDA’s UDI (unique device identification) final rule, published in September 2013.

Table 1 contains a review of the key factors to consider when comparing the available marking technologies. In addition to these factors, there are also production line implementation considerations to be taken into account (like whether the part is moving or static), what access you have to the part, what to do if there are multiple materials or point of use, and remote operations and programming.

Marking Technology Pros And Cons

Inkjet Marking

Inkjet marking is an on-the-fly, non-contact marking process, accomplished by forcing pressurized ink through a nozzle. There are two inkjet system types, drop on demand (DOD) and continuous ink jet (CIJ). In either case, the part must be moving to make a mark.

DOD creates a mark with an array of nozzles that simply deposit a dot on the material without steering. The spacing of the nozzles and size of the arrays governs resolution and mark size.

CIJ creates marks using charged ink droplets that are deflected perpendicular to the part movement direction in order to create characters. Rows of ink droplets are applied to the product, forming a dot-matrix character as the part moves past the nozzle. Character height (top to bottom) is determined by applying a voltage to each individual drop, which deflects drops to the appropriate position along the Y-axis. The printer’s stroke rate and the line speed of the moving product determine the character’s width (X-axis).

Table 2 lists the method’s key pros and cons. Figure 1 shows a schematic of the equipment along with a photo.

Figure 1: Schematic of contiuous ink jet (CIJ) method and picture of equipment

Dot Peening

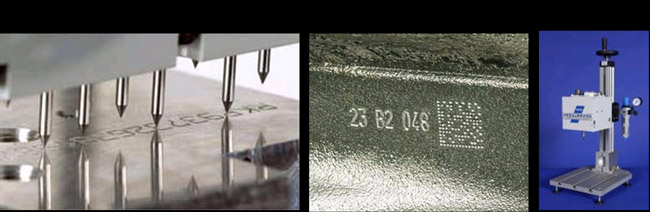

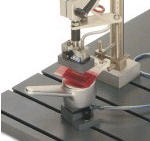

Dot peening, or pin stamping, is a contact marking process in which pneumatically or electromechanically driven single or multiple carbide styluses create a mark by physically indenting the surface of the material by impact. The stylus is mounted on XY stepper motors to create the mark pattern. Critical to the readability of a dot peen mark are the indent’s shape, size, and where relevant, spacing. The indented line or dot created should trap or reflect light and be large enough to be distinguished from the part’s surface roughness. Therefore, mark contrast is created by ambient light, and will only be viewable from certain angles. For Data-Matrix codes, the lighting is key to being able to read the code. Figure 2 illustrates the dot peen mark and equipment. Table 3 details the method’s pros and cons.

Figure 2: Multiple stylus engraver, typical mark in aluminum, and dot peen equipment

Electrochemical Etching

This contact marking process requires a mask, an electrolyte solution, and an electrode marking head. The mark is created as material is removed by forced corrosion according to the mask in various degrees to produce an oxide black surface effect, or an etched mark where the image is engraved into the material. The area to be marked must be cleaned, the pre-produced mask is then fixed onto the part, the mask is then coated with the electrolytic solution, and finally the electrode contact is made. Marking time may be seconds or hours depending upon the mark’s penetration. The multi-step process required slows down the marking speed to a certain extent.

This process is an excellent way to mark hardened and thin metals. Although contact is required to form a closed circuit, negligible force is applied during the process. The method etches material to a depth of 0.0001” in around one second and up to depths of around 0.01”. Dark marks on stainless steel are created in seconds.

Chemical etching requires proper disposal of the used chemicals, either by using wastewater treatment equipment or contracting with a certified third-party disposal company, which adds to its cost. Although the equipment can be low-cost, actual implementation at a facility can be quite high throughout the life of the product, due to the need for a wastewater filtration system or certified third-party disposal, as well as the solutions and stencils used to create the markings. The filtration system will need upkeep and the liabilities are far greater, because you are dumping chemicals through a filtration system into public water systems.

Table 4 notes the key pros and cons of this process. Figure 3 shows the method in action.

Figure 3: Electrochemical etching with electrode, mask, and applied electrolyte

Laser Marking

Laser marking, a fast and clean marking technology, is rapidly displacing and replacing older product marking technology. Easy and flexible automation, improved environmental profile, and low cost of ownership add to the benefits of the technology.

Several major laser marking choices are available, each one with specific marking characteristics that align best with particular materials and applications. Laser choices include ytterbium-doped fiber (Yb:fiber), neodymium vanadate (Nd:YVO4), green (532 nm), ultraviolet (UV), and carbon dioxide (CO2). In addition, neodymium-doped yttrium aluminum garnet (Nd:YAG) is an older technology that is still being used in the high power market, but has largely been superseded by one of the others listed.

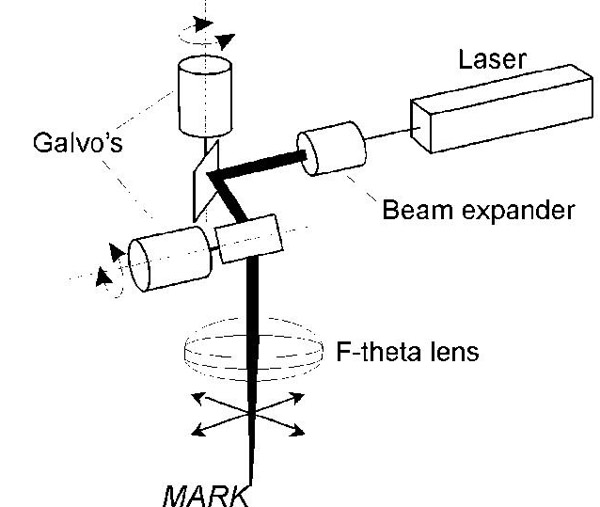

Each marking system has the same basic design Neodymium: vanadate — the laser is steered by mirrors mounted onto galvo motors to produce the mark. Each mirror moves along a single axis. These galvos move extremely quickly with very little inertia, and so can write marks at high speeds. The beam is focused using an F-Theta lens that produces a focus across the mark plane. Table 5 examines the method’s general pros and cons, and Figure 4 is an illustration of the key components of a laser marking system.

Figure 4: Schematic of a general laser marking system

Conclusion

Each method discussed has a variety of pros and cons, and Table 6 provides a general side-by-side comparison. On balance, laser marking is the most versatile of the DPM methods, with benefits including superior permanent mark quality; highly flexible marks that can incorporate text, graphics, logos and data codes; and a wide range of markable materials. In addition, laser marking is a high speed process that is easily integrated into the manufacturing line. Safety is enhanced because laser marking is a non-contact process with good standoff distance, and the lack of chemicals makes it environmentally preferable.