3M™ Steri-Vac™ Sterilizer/Aerator GSX Series With 3M™ Cycle Programmer

The 3M™ Steri-Vac™ Sterilizer/Aerator GSX Series is a new option for a safe and low-temperature sterilization that uses the 3M™ Cycle Programmer to improve turnaround times and reduce costs when compared to contract sterilization.

The 3M™ Steri-Vac™ Sterilizer/Aerator GSX Series is made up of ethylene oxide (EO) sterilizer/aerators designed to be used with single single-dose 3M™ Steri-Gas™ 100% EO Gas Cartridges when sterilizing devices in the medical, pharmaceutical, veterinary, laboratory and other non-healthcare markets. These self-contained sterilizer systems can automatically aerate the processed load in the sterilization chamber after a device is sterilized. Instead of requiring floor drains and bulk tanks of ethylene oxide, these sterilizers only need a power source, compressed air, and exhaust vent lines for operation.

Key GSX Series Features:

- Available in GS5X and GS8X models

- Requires minimal floor space

- Free-standing, rack, or in-wall installation

- Single-door or double-door configurations

Customized Cycles: 3M™ Cycle Programmer

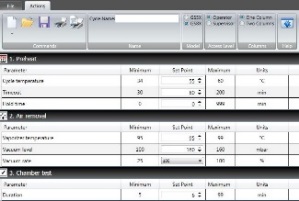

The 3M™ Cycle Programmer is a software program that permits the development of uniquely tailored and optimized EO processes for specified products. The software is capable of programing 28 different parameters in eight of the 9 active stages of the EO sterilization process. Operation is handled on a personal computer where custom cycles can be created and imported to the GSX Series sterilizer through a USB drive.

For more information on the 3M™ Steri-Vac™ Sterilizer/Aerator GSX Series and the 3M™ Cycle Programmer download the datasheet.

Ready to Optimize your Ethylene Oxide Sterilization Process?

Cost reduction and operations improvement are always a priority focus for medical device and pharmaceutical manufacturers, and contract service companies that support manufacturing.

See how 3M can help provide potential operational cost savings with their mini cost calculator.